T-slot aluminum profiles cutting and machining

Why choose the Alusic service? ...

How to make perfect grooves, millings or cavities on T-slot aluminum profiles?

How to get aluminum extrusions framing ready for assembly in fast delivery?

...The answer is only one: the Alusic service!

Products always available in stock! = Fast delivery!

Why so many companies choose our cut-to-length and machining service?

ADVANTAGES BY CHOOSING ALUSIC

1. Reduced processing times

Alusic invested in a machining and cut to length system that reduces the aluminium profiles cutting and drilling times thanks to the bar feeder, electrospindles and cutting unit that allow a continuous flow of machined and cut to size parts.

2. Maximum quality and precision in holes, cuts, counterbores and millings

The automatic numerical control system allows the machining of aluminium bars with the maximum precision starting from your design and avoiding human errors.

3. Modular aluminium profiles always available in stock

The purchasing planning system and the optimization of the supply flows of the 6-meter aluminium bars guarantee the constant availability of the material to be processed. Our logistics system also simplifies the picking and delivery of profiles to the cutting and machining line, reducing the turnaround on orders.

4. Reduction of the material supply times: delivery in 1/3 the time!

The constant availability of extruded aluminium bars and the automatic cutting and machining system allows us to deliver the requested material 3 times faster.

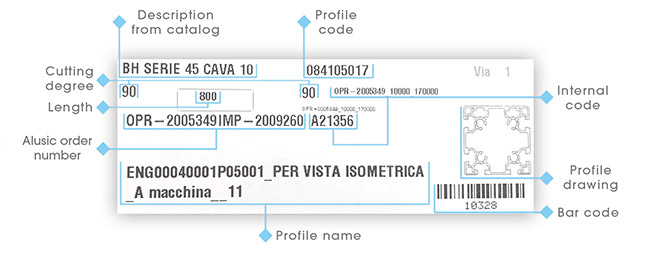

5. Quick identification of the ordered material

The labelling of each individual cut, machined and drilled t-slot profile allows the customer to identify all the sections of the profile as reported in his drawing.

Types of T-slot extruded aluminium profiles processing

We can perform high precision aluminium profiles machining such as:

STANDARD DRILLING

Standard drilling from diameter M3 to M12

THREADING

Threaded holes, made both as head threads and as threads along the bar.

| THREADING ON PROFILE HEAD | THREADING ALONG THE BAR | ||

| HOLE | Ø | HOLE | Ø |

| M4 | 3,3 | ||

| M4,5 | 3,75 | ||

| M5 | 4,5 | M5 | 4,2 |

| M6 | 5,6 | M6 | 5 |

| M7 | 6 | ||

| M8 | 7,4 | M8 | 6,8 |

| M9 | 7,8 | ||

| M10 | 9,1 | M10 | 8,5 |

| M11 | 9,5 | ||

| M12 | 10,3 | M12 | 10,2 |

CUTTING

Straight and inclined cut from 0° to 90°

COUNTERBORE

Counterbore, that is the creation of a cylindrical hole with a flat bottom, which widens another coaxial hole, usually used for the insertion of a hidden screw inside the slot of the extruded aluminium profile.

MILLING

The SLOT MILLING is an operation in which a groove is made on the surface of the aluminium profile allowing the screw to slide and to adjust its position.

PRECISE AND CLEAN MACHINING

The machining is completed with the removal of chips deriving from cutting, drilling and milling.

How to read the label on worked profiles

A label is affixed to each machined aluminium profile showing a series of data useful for the customer to recognize the pieces of structural profile requested, including the cutting inclination and the length, the bar code and the profile section showing the type of slot.